In order to solder laser diode die it is handy to have a hotplate small enough to fit under a microscope.

Accurate temperature control is required especially where several different melting point solders are used the same assembly.

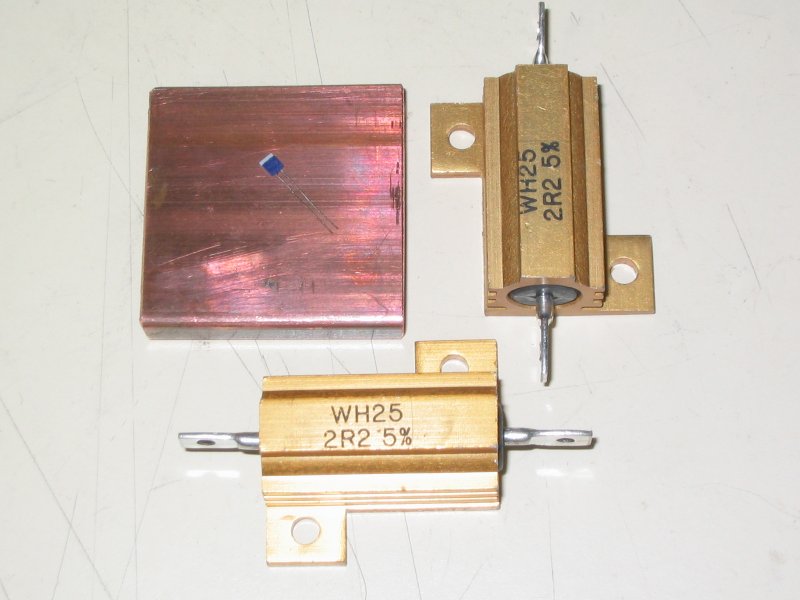

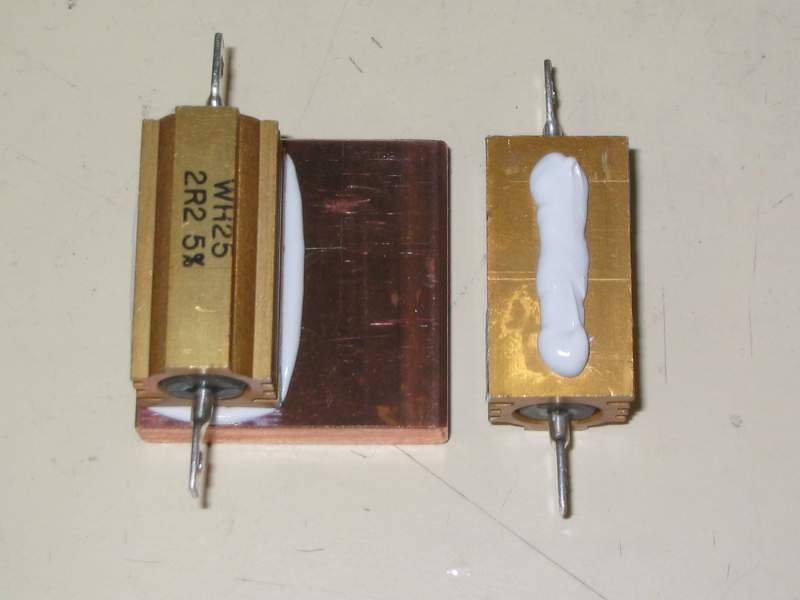

A simple miniature hotplate can be made from a couple of aluminium clad

resistors, a copper block and a PT100 temperature sensor.

Two 2.2 Ohm Welwyn WH25 resistors were chosen. If wired in

parallel this gives a heating power of 23W from a 5V supply.

Wired in series you get a heating power of 33W from a 12V supply.

The resistor's maximum temperature rating is 250 degrees C. If

PTFE covered wire is used for connections the hotplate may be used at

over 200 degrees C.

As well as the resistors you also require a PT100 temperature sensor and a 32mm x 32mm x 6.3mm copper block.

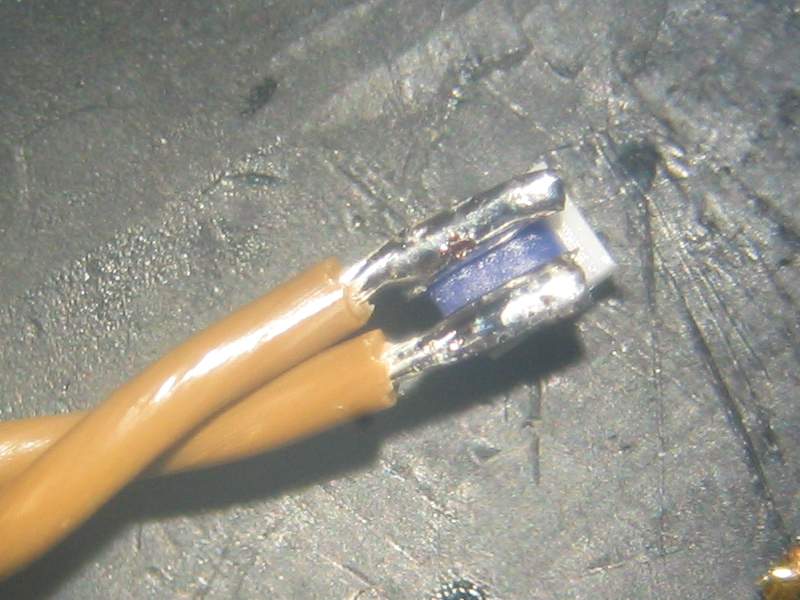

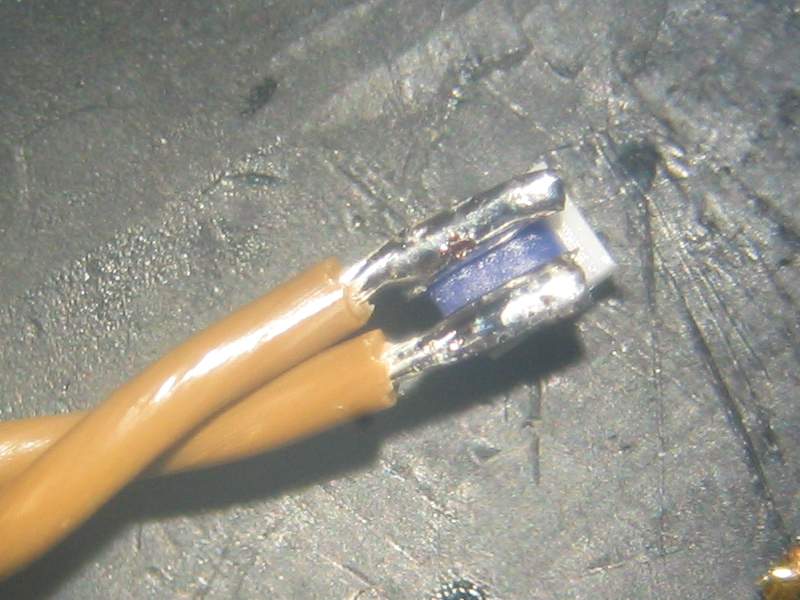

The wires on the PT100 sensor should be folded over the top of the

sensor and cropped. You can then solder extension wires to the

sensor.

The wires should be PTFE insulated and be of a sufficient wire gauge to

have negligible resistance compared to that of the sensor.

The copper block should be drilled and tapped in a couple of

places to allow you to fix your diode mounts to it for soldering.

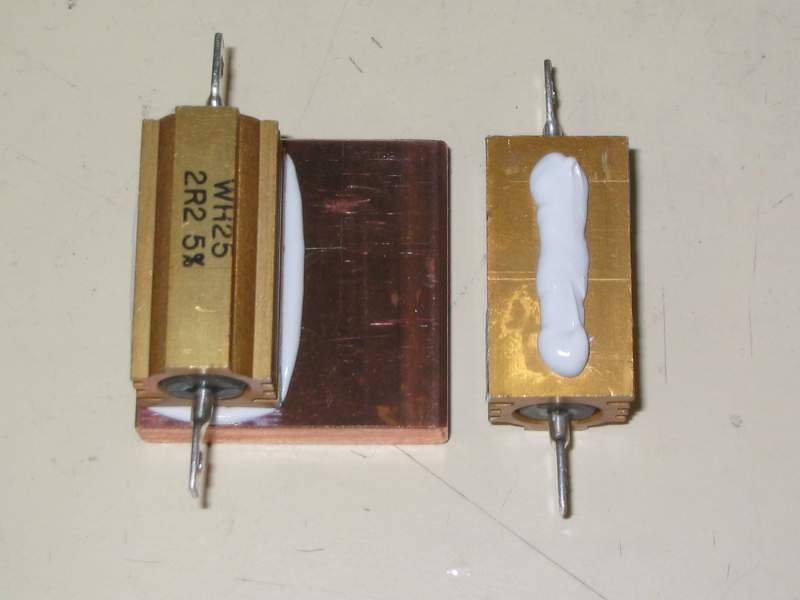

To make the assembly as compact as possible I have sawn the mounting lugs from the resistors.

They are fixed to the copper block with thermally conductive RTV silicone.

The PT100 sensor is placed in a bead of the thermally conductive RTV

silicone, between the two resistors and as close to the copper block as

possible.

The resistors and wire from the PT100 sensor are tacked in place

with rubber loaded Cyanoacrylate (black) while the RTV silicone

cures.

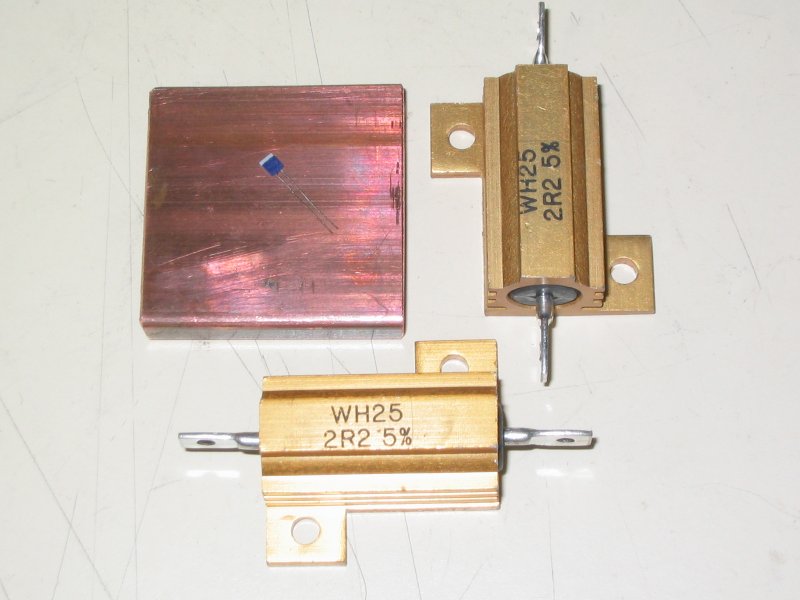

Once the RTV has cured the Cyanoacrylate may be chipped off and the excess RTV removed with a scalpel.

A fillet of Silicone RTV rubber is then placed between and at the ends

of both resistors to mechanically secure the resistors to the heatsink.

Underside of the finished assembly. A suitable controller for this hotplate is shown on the D4Thing page.